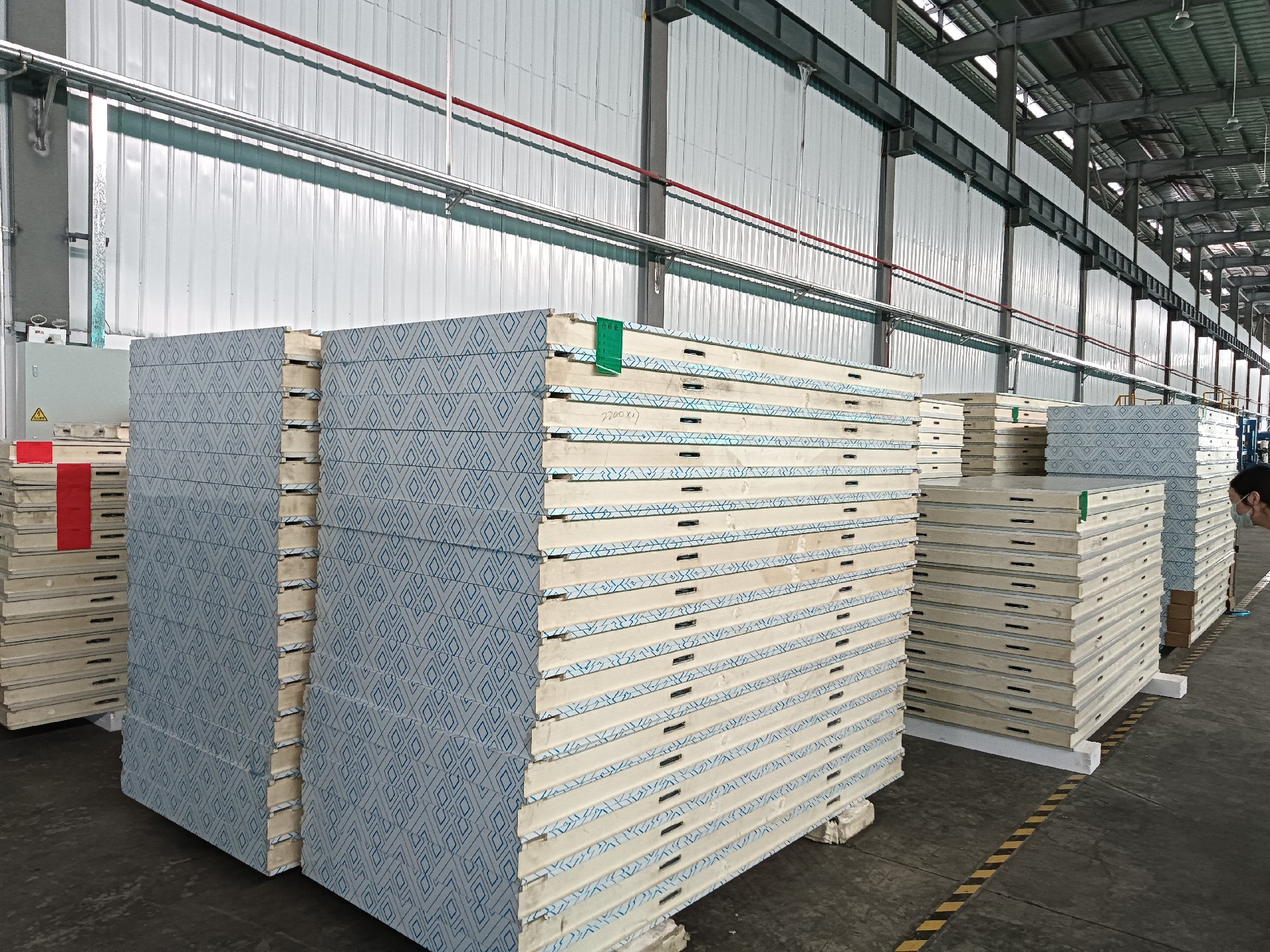

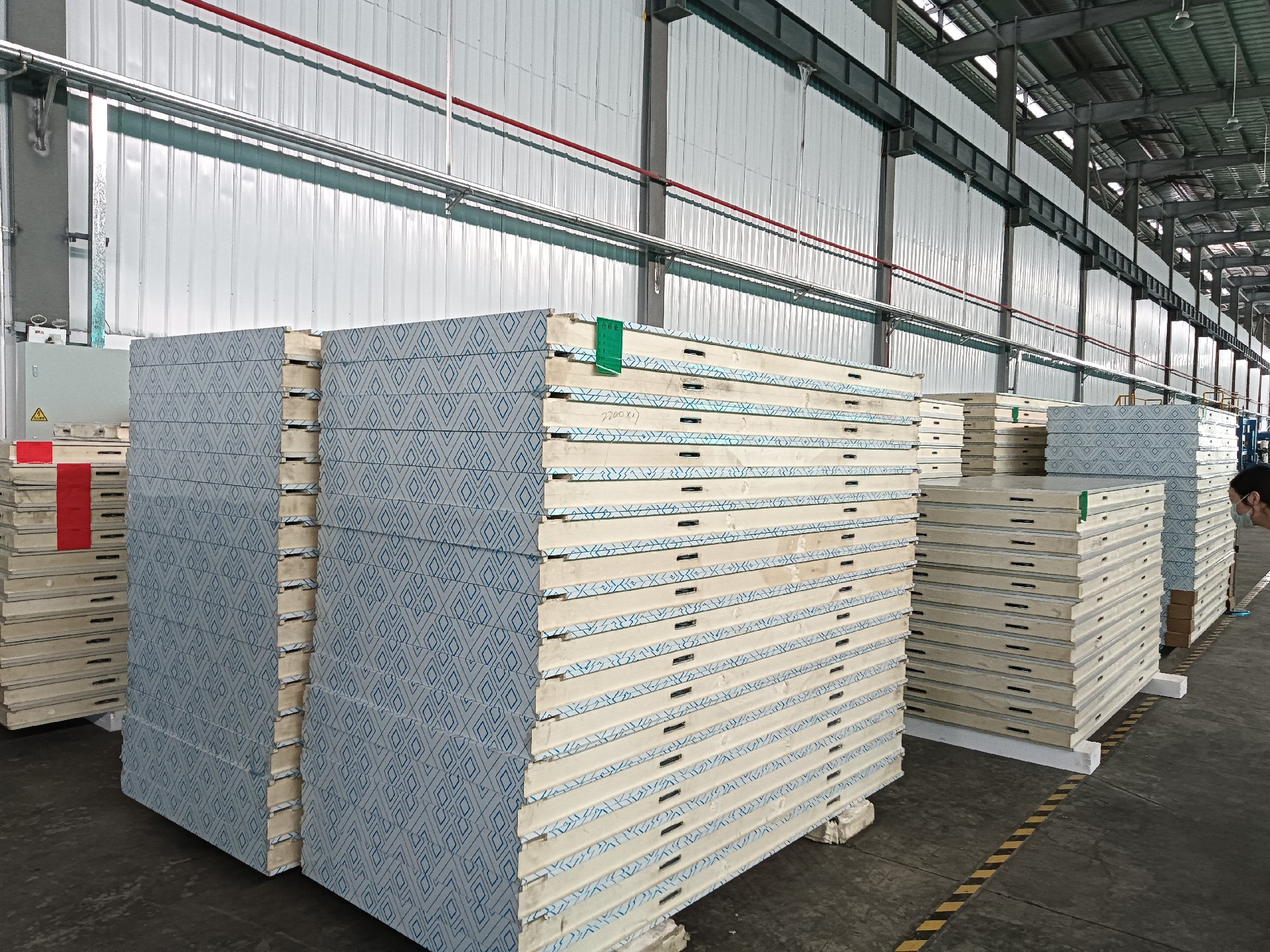

A common misconception in cold storage construction is that panel thickness is the primary factor determining energy efficiency. Industry experts are urging users to recognize the critical, overlooked variable: polyurethane (PU) panel density. New data shows that when panel thickness is the same, density is the deciding factor in operational electricity costs and long-term facility performance.

Density: The Silent Energy Saver

A recent three-month comparison between two identical cold rooms, differing only in panel density, revealed a significant finding: panels with lower initial cost (due to lower density) resulted in substantially higher long-term electricity consumption.

Here is why panel density (38–42 kg/m³) is crucial:

Superior Insulation Performance: Higher density leads to a better closed-cell structure in the PU core, resulting in a lower thermal conductivity . This maximizes insulation and minimizes heat transfer.

Enhanced Durability: Low-density panels are prone to deformation and collapse over time, leading to unexpected maintenance and repair costs.

Moisture Resistance: High density increases the closed-cell ratio, providing superior resistance to water vapor penetration and condensation. This prevents the core material from degrading, especially in high-humidity environments (e.g., seafood freezers).

Conclusion:While thickness sets the foundation, density dictates the outcome in cold storage efficiency. Initial savings from choosing low-density panels are quickly negated by increased energy expenditure over the operational life of the facility. Investing in the optimal density range of 38–42 kg/m³ is key to securing low energy bills and overall reduced life-cycle costs.

marketing@brdecogroup.com

marketing@brdecogroup.com +86 13318205907

+86 13318205907 EN

EN EN

EN CN

CN FR

FR

Message

Message WhatsApp

WhatsApp